Tensile type/transparent sheet

"Teijin Mirai Studio"

the certain factory

the certain office

A smoke-proof hanging wall is a smoke-proof wall that constitutes a smoke-proof

section stipulated by the Building Standard Act, and the wall hanging more than

50 cm from the ceiling blocks the flow of smoke in the event of a fire.

making it possible to extend the evacuation time as much as possible.

Fires are not the only disaster. Due to large-scale earthquakes such as the Great East Japan Earthquake and the Kumamoto Earthquake, there have been many secondary disasters in which the glass of smoke-proof hanging walls installed to protect human lives is shattered and injured.

The sheet is made of non-combustible sheet that boasts the industry's top-class transparency, which has been certified as non-combustible by the Ministry of Land, Infrastructure, Transport and Tourism. In addtition to high transparency , it has an antistatic function, so it is difficult for static electricity and dust to adhere dureing work, and workability has been greatly improved.

The seat is made of non-combustible materials certified by the Minister of Land, Infrastructure, Transport and Tourism.

The weight is about 1/10 lighter than conventional netted glass.

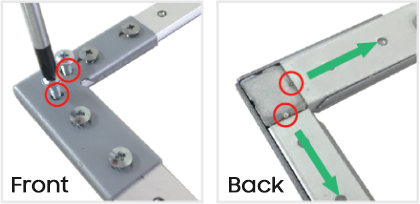

The tention of the seat can be adjusted with a single screw. Even if the seat sags due to an unexpected impact during transportation or construction, it can be solved on site without additional parts.

There is no need to bring your own spare panels.

Equipped with special materials that absorb damage caused by shaking. The frame itself greatly reduces the possibility of falling.※For tensile type

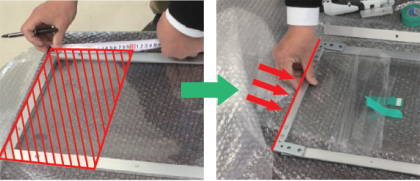

No special materials are required, and panels can be easily cut on site.

It can be installed with almost no restrictions on the shape of cellings, walls, and columns.

(Steps, circles, round pillars, etc. can be easily installed)

| characteristic | Name |

Thickness (mm) |

Mass (g/m2) |

Light transmittance (%) |

Surface Resistance (Ω) |

Specialty |

Non-combustible material certification number (Approved by the Minister of Land, Infrastructure, Transport and Tourism) |

|---|---|---|---|---|---|---|---|

| Transparent | U-CLEAR SHEET® K3 | 0.23 | 320 | 92 | 4×1010 | Anti-static | NM-5635 |

Obtained non-combustible certification (certified by the Minister of Land, Infrastructure, Transport and Tourism)

※The above data is a measured value, not a standard value.

| characteristic | Transparent |

|---|---|

| Name | U-CLEAR SHEET® K3 |

|

Thickness (mm) |

0.23 |

|

Mass (g/m2) |

320 |

|

Light transmittance (%) |

92 |

|

Surface Resistance (Ω) |

4×1010 |

| Specialty | Anti-static |

|

Non-combustible material certification number (Approved by the Minister of Land, Infrastructure, Transport and Tourism) |

NM-5635 |

Obtained non-combustible certification (certified by the Minister of Land, Infrastructure, Transport and Tourism)

※The above data is a measured value, not a standard value.

Constructed by transparent non-combustible sheet and aluminumframe. In the unlikely event that it sags due to a strong impact during transportation or work, it can be easily eliminated with the "Tention Adjustment Hall". In addition, the fit of the unit can be adjusted.

In the unlikely event that the seat sags can be adjusted on site without additional parts.

Size can also be adjusted on site(size down)

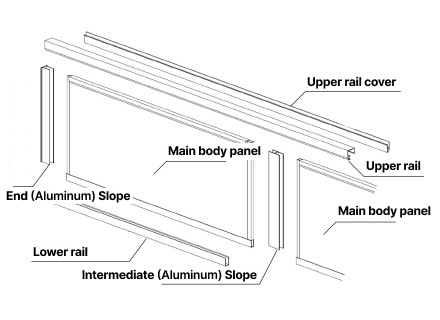

1. Attach the top rails to the ceiling.

2. Install the end rails.

3. Attach all the panels while hooking them to the upper rail.

4. Insert the middle square from the bottom into the panel intersection to make the final adjustment of the panel gap.

5. Install the lower rail and the upper rail cover in parallel.

6. Drill pilot holes and fasten them sequentially with screws.

7. Finally, remove the protective film and complete the construction.

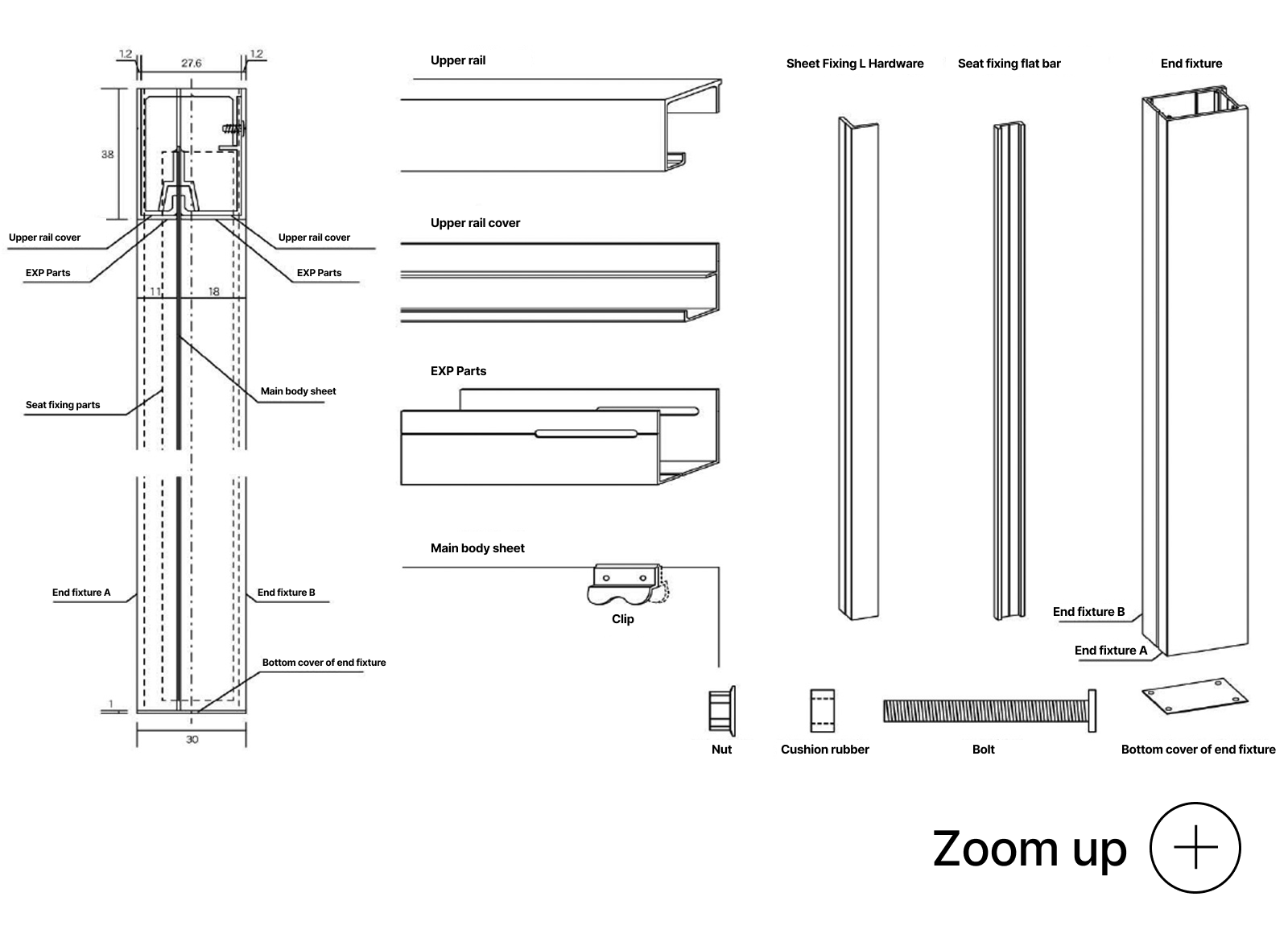

By absorbing the displacement generated when the entire building (structure) and the ceiling shake in different ways due to an earthquake with "shock-absorbing springs" attached to both ends, the possibility of the frame itself falling is greatly reduced and safety is improved.

The expansion structure on the inside of both ends further improves safety.

1. Attach the end fixtures to the walls and pillars.

2. Attach the top rails to the ceiling.

3. Cut the sheet on top of the floor curing.

4. Attach the fixing hardware to the sheet.

5. Attach the hanging clip to the sheet.

6. Hold each sheet fixing bracket and place it on the end fixture.

7. Finally, remove the protective film and complete the construction.

Tensile type/transparent sheet

Tensile type/transparent